Fyrn brought me in to take their "mom-and-pop" sized SF operation to a full blown production facility in Reno, NV.

Among many challenges, I was tasked to accomplish:

-Plan for and build out a new manufacturing facility for 400% increased output in year 2.

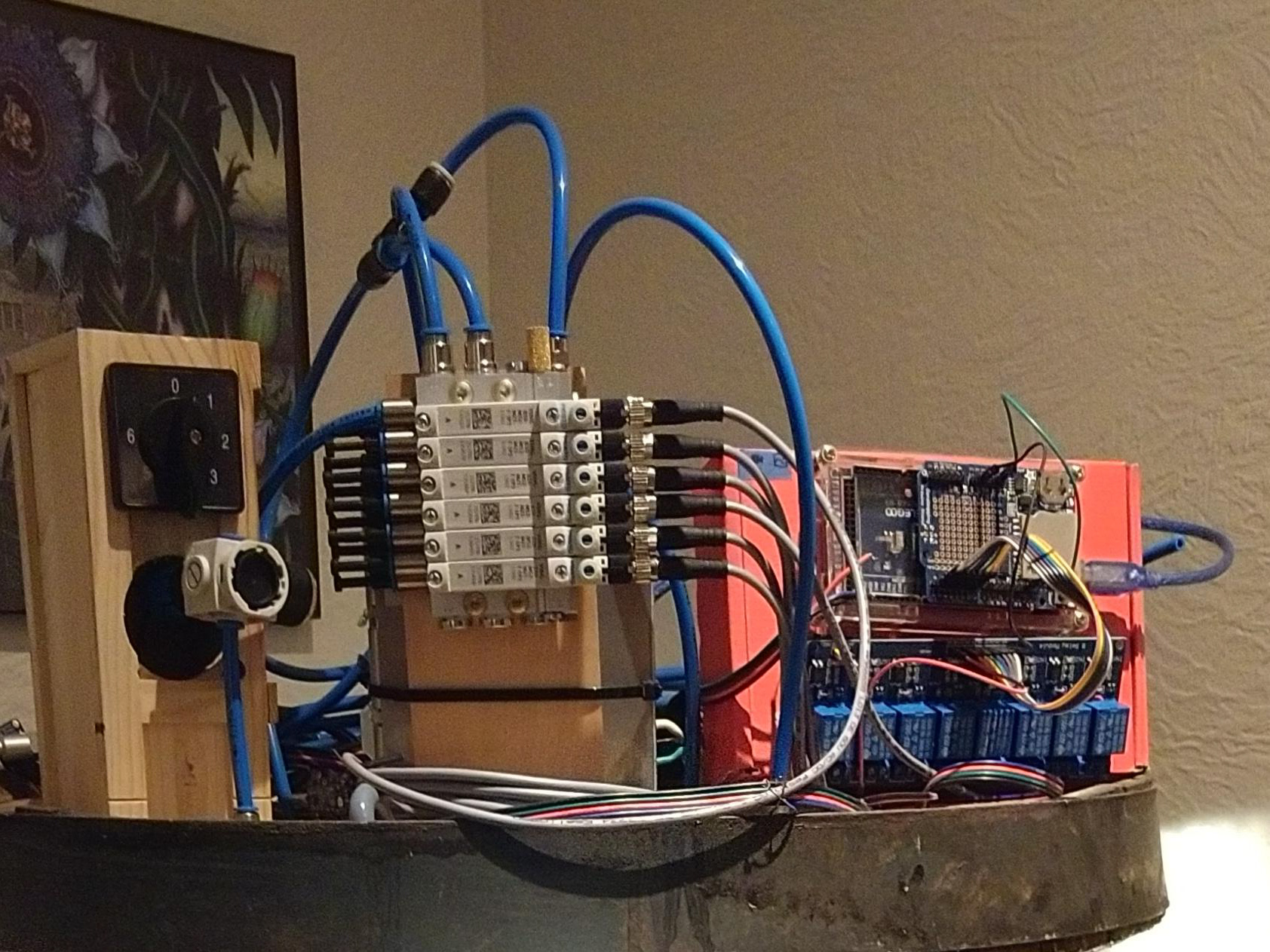

-Design, build, and implement 18+ unique machines.

-Design and build parts, and systems to manufacture wood and metal parts for high end furniture.

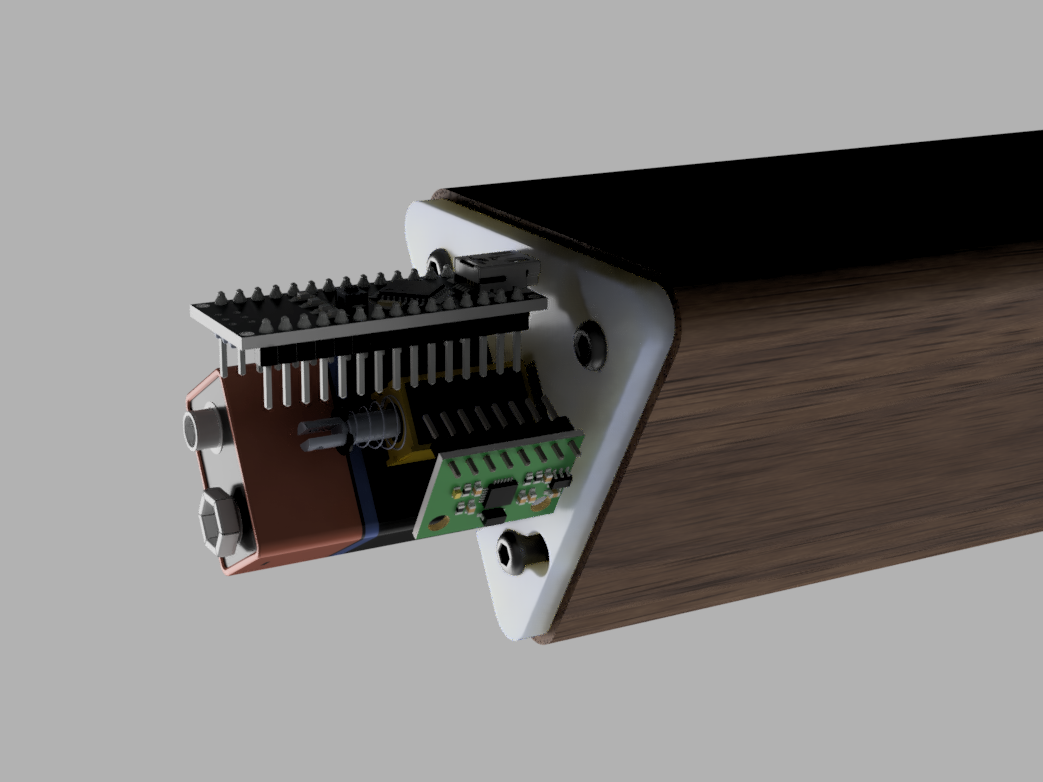

-Engineer parts through CAD, prototyping, and engineering drawings.

-Engineer parts through CAD, prototyping, and engineering drawings.

-Ensure all produced product parts meet +/- 0.004" tolerances and tighter, the highest standards in the industry.

-Manage production of custom parts both overseas and in house.

-Increase efficiency and decrease cost through assessing design, materials, usability, and human factors.

-Increase safety through SOPs, design, ergonomics, and safety features

-Increase efficiency and decrease cost through assessing design, materials, usability, and human factors.

-Increase safety through SOPs, design, ergonomics, and safety features

-Create and adhere to quality control standards, design QC tools, assess and resolve QC issues.

-Engineer flexible design with modularity, future-proofing for the growing product lines.

-Design for longevity and serviceability of manufacturing machines and products.

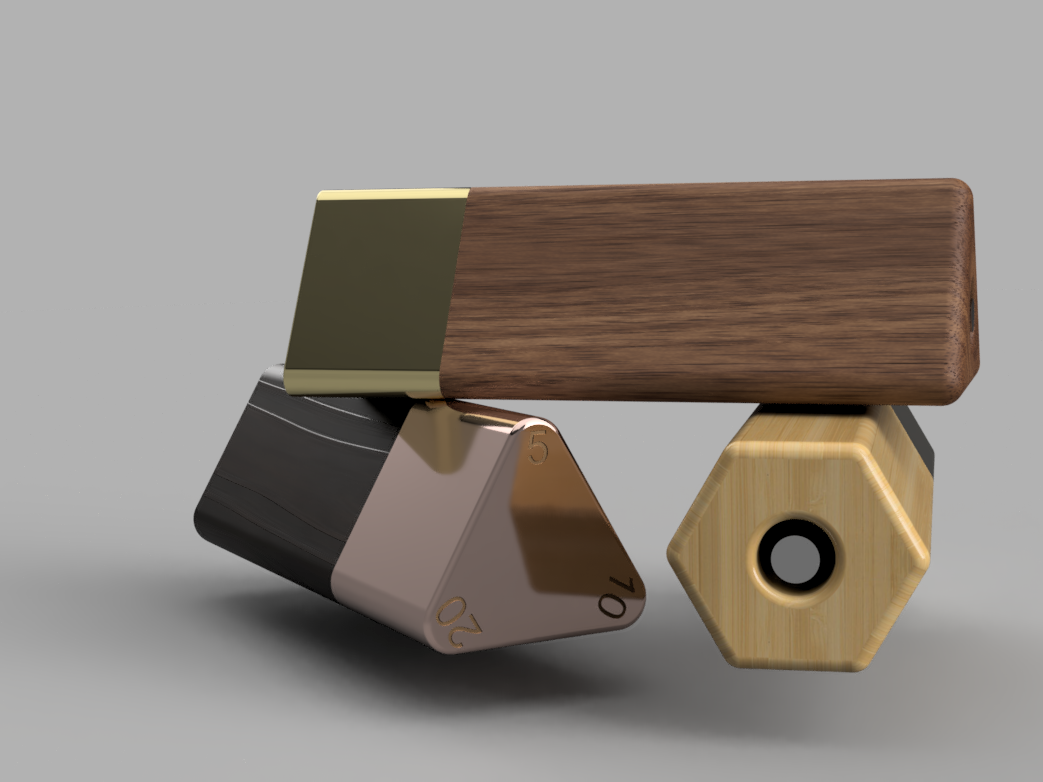

- Design and develop new product lines

-Engineer flexible design with modularity, future-proofing for the growing product lines.

-Design for longevity and serviceability of manufacturing machines and products.

- Design and develop new product lines

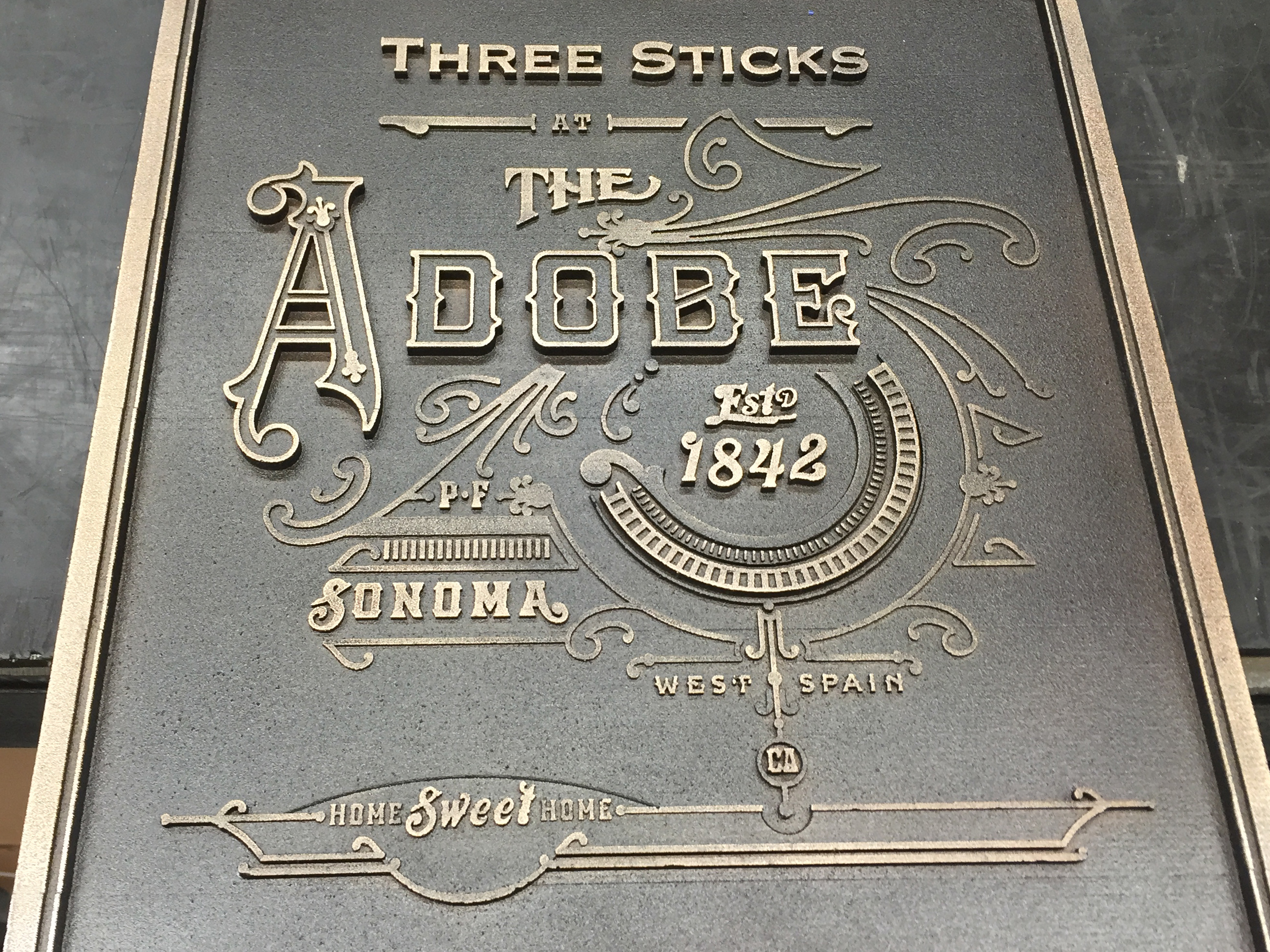

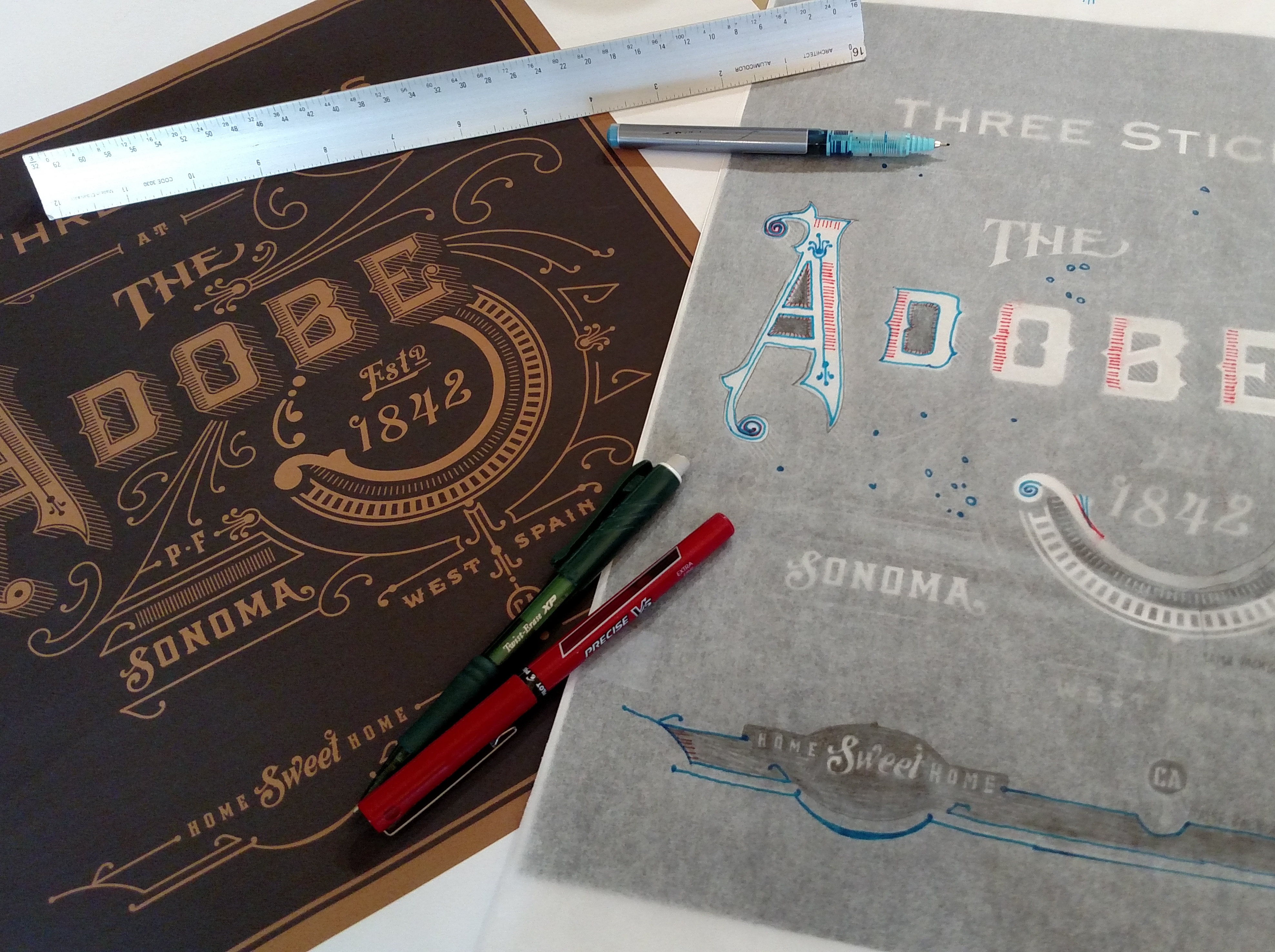

The New Shape of Craft